Cosmetic Airless Bottle

Cosmetic airless bottle is an airtight plastic bottle […]

Cosmetic airless bottle is an airtight plastic bottle used in cosmetic production process to preserve and adorn the cosmetic products for long time. Airless bottles are simply hollow bottles filled with either water, air or both. The airless bottles used in different stages of cosmetic production are usually used on cosmetic products which need utmost perfection before they are released into the market for sale. Such airless cosmetic bottles save both time and money. It also helps manufacturers to make a final product according to their specifications without deviating from the original concept and design. These airless cosmetic bottles contain no gases, gaseous substances or chemical which may cause any kind of allergic reaction on human skin.

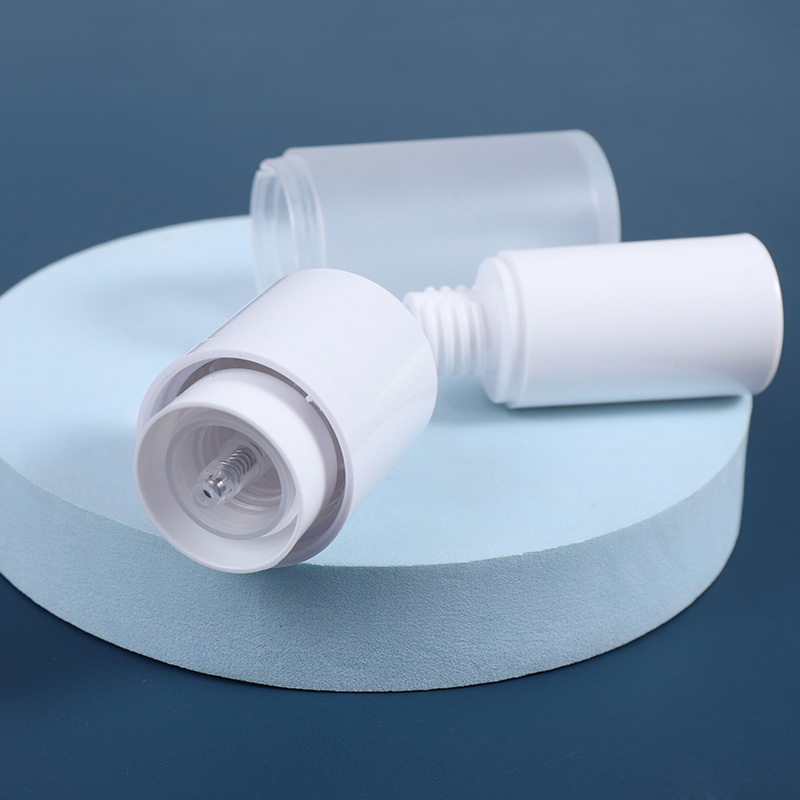

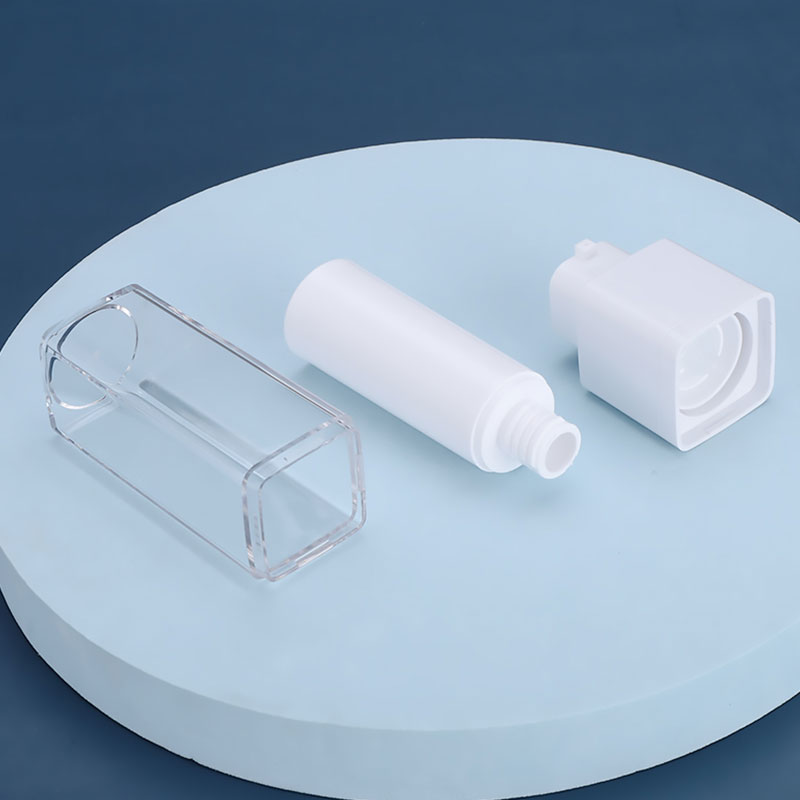

A cosmetic airless bottle can be broadly divided into two types the first one is called as vacuum bottle and the other one is known as bottle packaging machine. This second type is preferred when the product we want to package is sensitive in nature as it contains no chemical, gaseous or biological matter. This product should be packed in a special airtight container using special methods and tools. We can also use our hands for packaging if the product is very simple in design.

Plastic containers can be broadly divided into three categories airtight plastic bags, reusable cloth bags and disposable plastic bins. As airless bottles we use either cloth or reusable paper bags or vacuum bags. These reusable or cloth airtight bottles are made up of polyethylene terephthalate (PET) and are available in a wide range of colors and shades. The bags are made up of high density polyethylene and have small holes on one edge. This type of cosmetic packaging is considered to be highly effective as it provides a good protection to the raw materials. Moreover, it also reduces evaporation of chemicals and undesirable gases.

Another important feature of this cosmetic packaging is that it prevents the escape of moisture while inside the bottle body. Due to this feature the products keep their gloss and shine for a longer period of time. If we look at the benefits offered by high-end vacuum packing, then it is evident that these bottles provide excellent packaging solution for all the high-end cosmetic packaging requirements.

As discussed above, vacuum packaging offers a number of advantages for cosmetic packaging. It is an eco friendly packaging system. It is an efficient packaging system and very easy to maintain. It has the capability of withstanding any kind of environment. It is an economical packaging system and it uses the best of vacuum pumps and high-end quality raw materials.

High-end vacuum pumps carry high-tech color-coded vacuum bags which help to produce fine labels on the bottles. The bottles can be easily recognized because they contain color coded foam inserts which help to produce the necessary labeling on the bottles. The packaging process is a pain-free one. The entire packaging process is made simple with the help of high-end vacuum pumps. It can be customized according to our requirement with the help of high-end graphic printing technology.