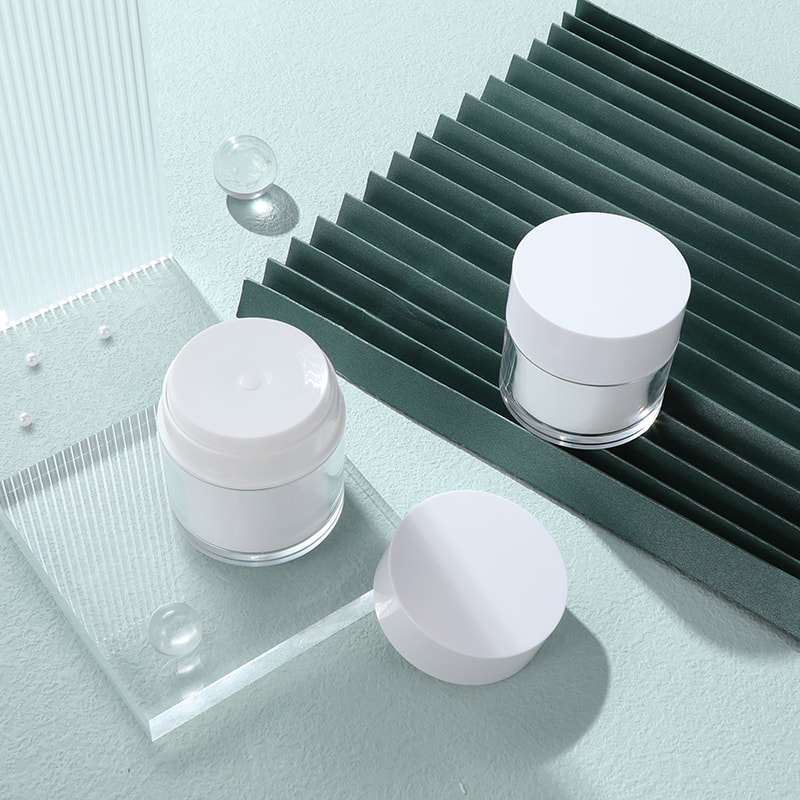

What is the difference between cosmetic packaging sealing performance test and impact resistance test

Cosmetic packaging sealing performance test The sealing […]

Cosmetic packaging sealing performance test

The sealing performance test can ensure that the sealing of the entire product package is intact, and prevent the leakage of the product from causing deterioration of the packaged product due to the poor sealing performance.

1. mfy-01 sealing tester: vacuum chamber is used to test the reliability of packaging and sealing. Microcomputer control, panel operation, digital setting test parameters, fully automatic test

2. lssd-0 leakage and sealing strength tester: testing the heat sealing strength and sealing integrity of packaging bags, plastic bottles, packaging containers, intelligent testing process, liquid crystal display, statistical communication; positive pressure principle

Impact resistance test of cosmetic packaging

Test the impact resistance of packaging materials to ensure that the selected packaging materials can effectively protect the product. The impact resistance test has two test methods: falling dart impact and pendulum impact.

1. bmc-b1 falling dart impact tester: free falling dart test method, measuring the impact mass and energy of a plastic film or sheet under a given height of free falling dart impact, when the sample is broken.

2. The fit-01 film impact tester is used to determine the impact resistance of plastic film, sheet, composite film, aluminum foil and other materials. The hemispherical punch of the film impact tester impacts and passes through the film sample at a certain speed for measurement. The energy consumed by the punch is used to evaluate the pendulum impact resistance of the film.