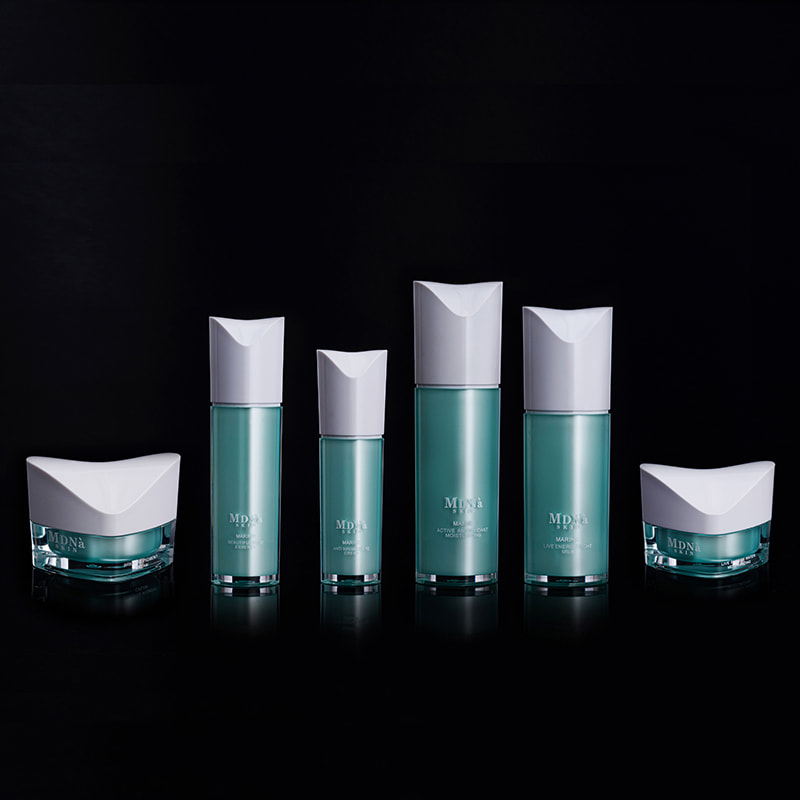

What Is A Lotion Dispenser Pump Factory?

Lotion Dispenser Pumps are typically used in salons o […]

Lotion Dispenser Pumps are typically used in salons or spas to dispense cool, concentrated liquid makeup like foundation and concealer. They are most often used in nail salon applications, hair removal, makeup application, and much more. Lotion pumps have many different parts including the pump, the reservoir, the tubing, and the cover plate. Most of the time, the pump is located near the dispenser base and is used in conjunction with one, two, or three other types of Lotion Dispenser Pumps.

The plastic bottle that the Lotion Dispenser Pump factory comes in is made out of a variety of materials. In some cases, the plastic is just a standard clear bottle. Other times, it is constructed out of a material called polystyrene. In other words, the plastic used for a lotion pump bottle is translucent and not transparent. While this does tend to make the plastic liquid soap dispenser pump more expensive and difficult to find, it also makes the Lotion Dispenser Pump very useful in that it can dispense an incredible amount of product with a relatively small amount of space.

The Lotion Dispenser Pump factory will typically have a series of holes drilled in the top of the plastic bottle to allow the access of the water hose to the cover plate. Once the hose is in place, the holes will be plugged with small caps. These caps will keep the water hose from freezing while it is in use. Once the Lotion Dispenser Pump has begun to work, it will begin to dispense a small amount of soap at a time in small batches.

As the Lotion Dispenser Pump factory machine works, it creates gallons of clear solution that is pumped into the can. Sometimes, depending on the brand you are using, the solution will be mixed with water. However, most brands contain plastic beads or foam that do not mix well with water. When this happens, the bubble foam is usually wasted because it does not look as good as it did when it was first dispensed. However, the plastic lotion pump will typically make sure to mix the solution with the water every time the machine runs.

The Lotion Dispenser Pump factory machine will run for approximately four hours before it shuts off automatically. The machine should shut down by itself after four hours so that you can empty the container completely. If you do not complete this process, the bubbles may get stuck on the sides of the can, causing them to harden up and harder to remove. While the plastic soap dispenser pump factory does its job, you should also clean the dispenser on a regular basis. It is important to ensure that the can is always clear and that the dispenser is working properly.

The Lotion Dispenser Pump Factory is a wonderful personal care cosmetic pump dispenser. It has several features that will make cleaning your dispenser much easier and allows you to fill larger containers without wasting any of your lotion. However, if the plastic in the Lotion Dispenser Pump Factory is not properly cleaned, it can cause problems. It is important to ensure that the plastic beads and foam in your Lotion Dispenser Pump Factory are properly cleaned on a regular basis. This will help you to make sure that your personal care cosmetic pump is working properly, and will help you to keep it in good condition.