Material selection instructions for plastic cosmetic packaging bottles

1. The materials used for plastic packaging bottles are […]

1. The materials used for plastic packaging bottles are usually pp, pe, K material, as, abs, acrylic, pet, etc.

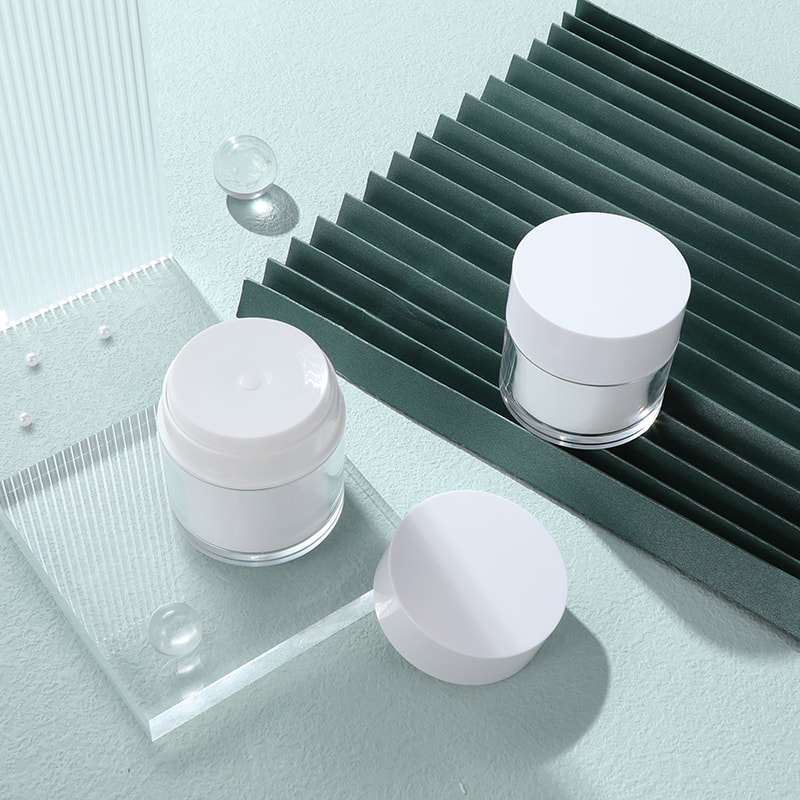

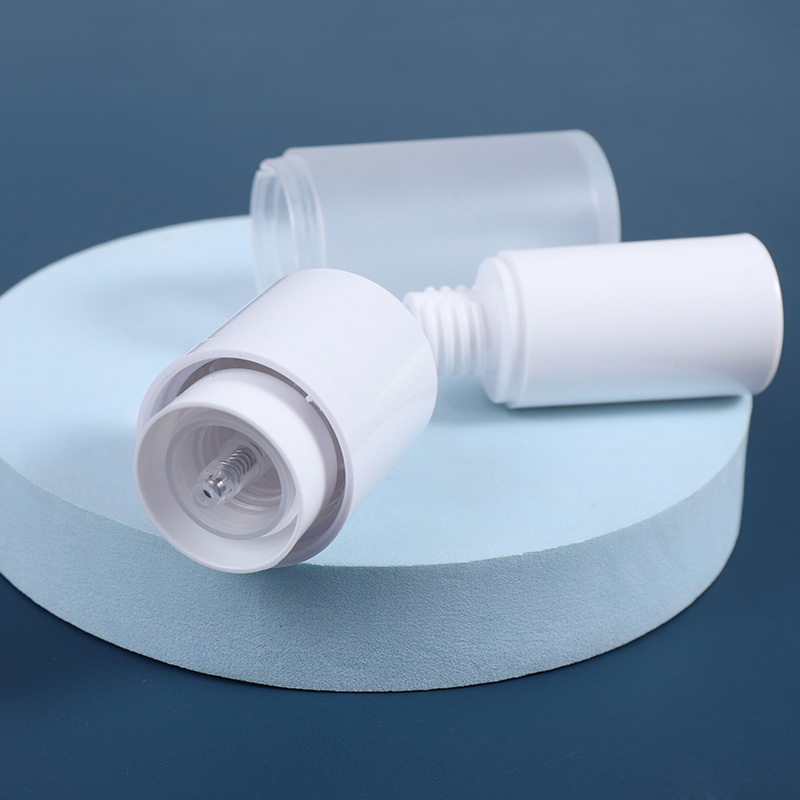

2. Cream jars, lotion bottles, matching caps, stoppers, gaskets, pump heads, and dust covers commonly used in the cosmetics and daily chemical products market are injection molded; pet blowing is a two-step molding: first, injection molding The tube embryo is made by the method, and then the finished product is made by blowing the bottle; other containers such as emulsion bottles with thinner walls and washing flat are blown bottles.

3. The pet material is an environmentally friendly material, with high barrier properties, light weight, not easy to break, chemical resistance, high transparency, etc., suitable for making pearlescent, colored, magnetic white, transparent and other packaging bottles. It is used in the filling of gel water. Wide range of applications.

4. Acrylic is made of injection molding bottle, which has poor chemical resistance. Generally, it cannot be directly filled with paste. It needs to be blocked by an inner tank. The filling should not be too slow to prevent the paste from entering the liner and the acrylic runner and then cracking; After the cream bottle is scratched, it is obvious that the bottle is free, so the requirements are higher in the packaging and transportation process; the acrylic bottle has high permeability, sensory bottle wall thickness, thick and generous, but the price is expensive.

5. As transparency is higher than abs, and toughness is better.

The user can customize the packaging color, usually do the primary color frosted and magnetic white, or add pearl powder effect. Generally, the main container and the matching cover need to be matched with the same color master, but in the production process due to the selection of the material part of the container and the matching cover Similarly, the appearance of the color effect will be different.

The surface screen printing materials are ordinary ink and uv ink. The uv ink has better effect, gloss and three-dimensional effect. It should be printed before the customer confirms it. The screen printing effect on containers of different materials will be different.

The effect of bronzing and silver bronzing is different from that of printing gold powder and silver powder. The surface of the main container is hard and smooth, and it is suitable for bronzing or silver bronzing, while the surface of soft bronzing, printing effect is not good and easy to fall off; Better gloss than printing process.

Plastic packaging bottles are generally equipped with inner gaskets, pull caps, and inner plugs. Very few are also equipped with small spoons or droppers. The main consideration is its tightness and ease of use.