What is Makaron cream bottle?

The cream in glass bottles cannot be put in one bottle, […]

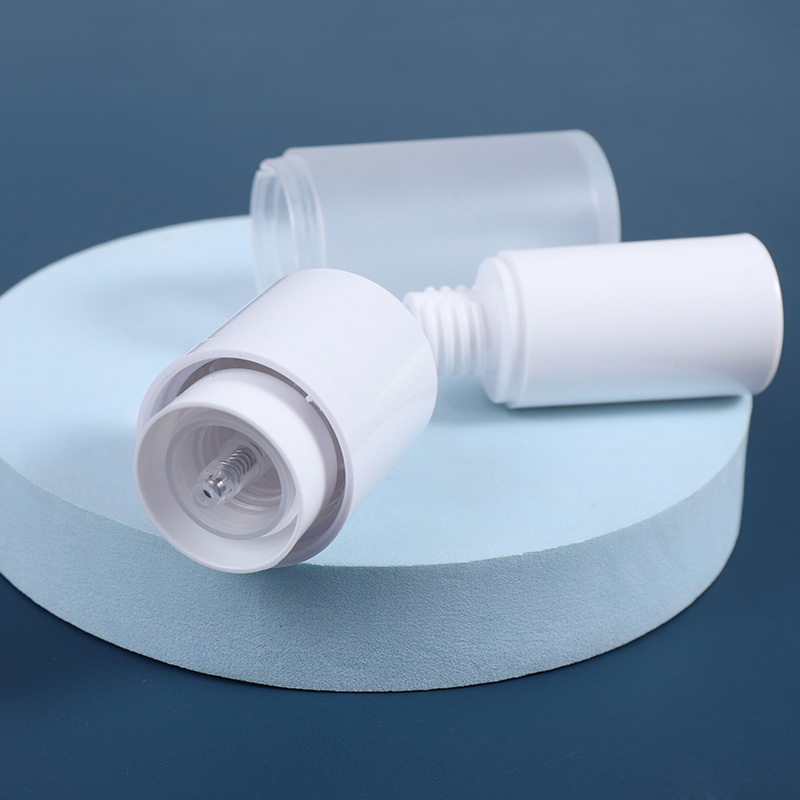

The cream in glass bottles cannot be put in one bottle, because the cream itself is a very viscous liquid, so the cream in sub-bottles cannot be put together, because different brands cannot be put in one bottle, so if the cream in sub-bottles is very small, it can be put together. The cream bottle has the function of keeping fresh, which can effectively prevent the deterioration of the product in the process of transportation, storage and use. At the same time, the characteristics of the cream can keep fresh make it suitable for the preservation of various foods, which can well solve the deterioration of the product during the preservation period. The cream bottle is a container used to hold cream. It is usually made of metal or glass and used to hold cream and powder. Usage of cream bottle Cream bottle is generally used to hold cream, cream, liquid, oil, emulsifier, essence, cosmetics and other cream bodies, so that they can prevent moisture and dust. General classification of cream bottles: according to the material classification of cream bottles, cream bottles can be divided into aluminum alloy and plastic. The cream bottle is characterized by good moisture-proof and dust-proof effect and can well preserve the product. Cream bottles are used to store medicines. 2 It can be used to store cosmetics, skin care products, face and body protection products. General cream bottles are used to store cosmetics, daily protection and other products

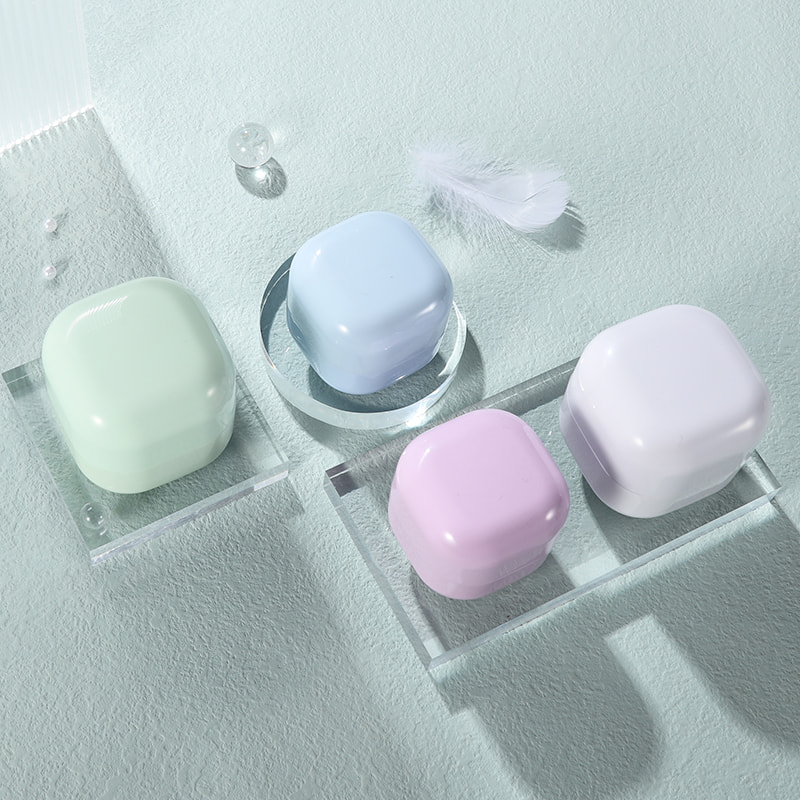

This Makaron cream bottle meets the fantasy of beauty. Macaron first appeared in Italian monasteries, was made into desserts, and then promoted, and later evolved into a brand. How many girls can resist Makaron's preference? The shape is a cute little cube, and the color is beautiful Makaron