How to choose spray bottle packaging materials

In the field of cosmetic packaging, cosmetic spray bott […]

In the field of cosmetic packaging, cosmetic spray bottle packaging makes the application of cosmetics more diversified. In the past, perfume bottles used the cap style, so it was obviously difficult to spray evenly on the smell. The spray bottle style has been greatly improved. However, with the development of technology in the market, the choice of spray bottle packaging materials has become diverse. How to choose spray bottle packaging materials has become a problem considered by many cosmetics companies. Then Yuyao Longzhuang Plastic Co., Ltd will take you to understand spray bottles to help companies better To promote products locally, it is necessary to select packaging materials suitable for their characteristics for various spray products.

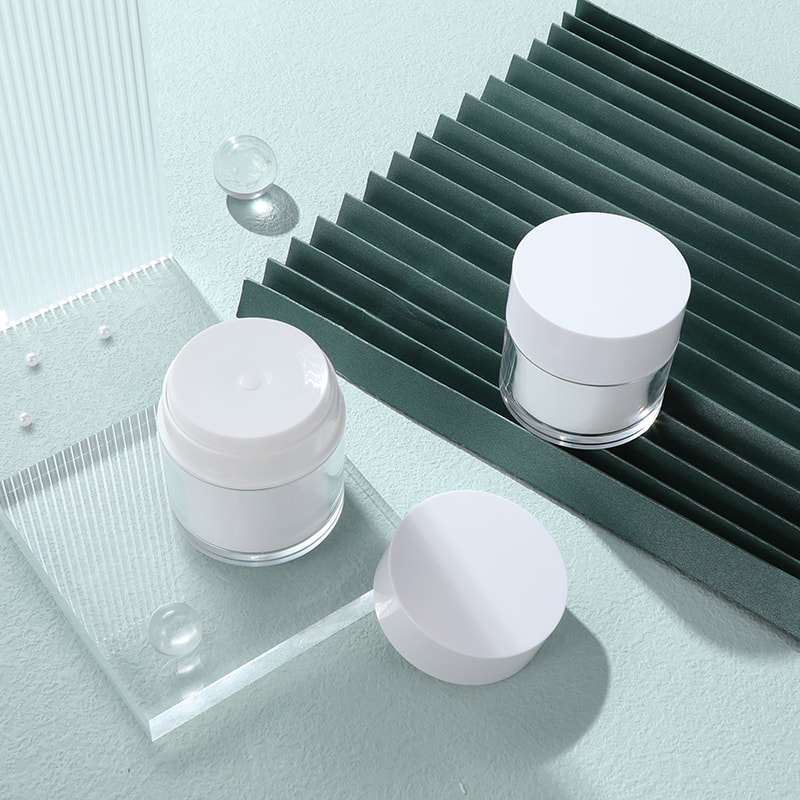

Regardless of whether it is the main packaging material or the auxiliary packaging material, it must meet the functions of packaging in the circulation process, that is, under the premise of protecting the product, facilitating transportation, and promoting the three basic functions of sales, but also undertakes such as improving product taste and commending brand culture , Responsibility to enhance brand value.

In addition, during the entire process from filling to consumer use, the main packaging material has always been in direct contact with the spray product, so the quality of the packaging will directly affect the consumer's judgment on the quality of the product.

So what aspects should be considered when packaging materials? What performance requirements should be met?

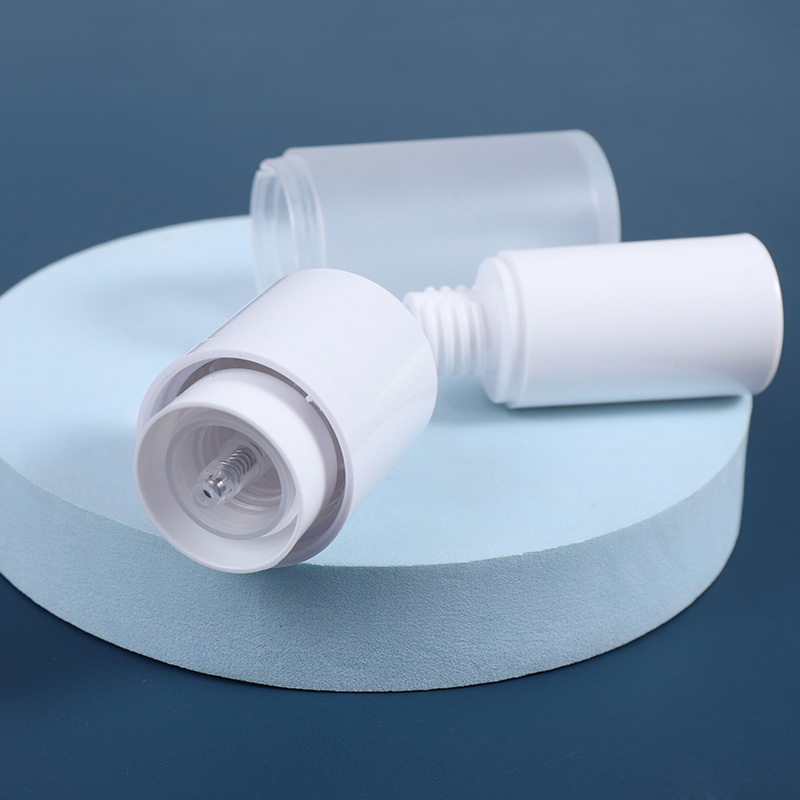

1. Mechanical properties

The packaging material should be able to effectively protect the product, so it needs to have a certain degree of strength, toughness and elasticity. To adapt to the influence of static and dynamic factors such as pressure, shock and vibration. This also requires specific analysis of specific issues.

2. Barrier performance

According to the different packaging requirements of the bottle, the packaging material should have certain barrier properties to moisture and light.

3. Sealing performance

The packaging material should be able to guarantee a certain degree of sealing performance, and there will be no product leakage when undergoing various environmental changes.